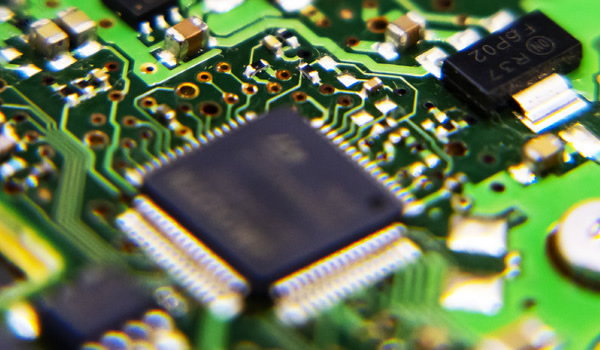

PCBA processing has environmental requirements for production and processing workshops, especially for SMT surface mount processing workshops, such as power supply, temperature and humidity, and dust-free conditions. Below, Guangzhou PCBA processing manufacturer Pete Electronics will briefly introduce the common environmental requirements of the processing workshop.

For most SMT processing workshops, the bearing capacity of the factory floor is greater than 8KN/m2, the vibration control is within 70dB, and the maximum value does not exceed 80dB; The noise should be controlled within 70dBA, and the power supply generally requires single-phase AC220 (220 ± 10%, 0/60Hz) and three-phase AC380 (380 ± 10%, 50/60Hz). The power of the power supply should be more than twice the power consumption, and these conditions can meet the requirements of normal PCBA processing.

The requirement for air source is also important in SMT surface mount processing. Generally, the factory's air source can be directly used, or an oil-free compressed air machine can be configured separately, and the pressure usually needs to be greater than 7kg/cm2. In actual production and processing, electronic OEM processing plants also need to perform oil, dust, and water removal treatment on compressed air.

Reflow soldering and wave soldering equipment need to be equipped with exhaust fans. For full hot blast furnaces, the minimum flow rate of the exhaust duct is 500 cubic feet per minute (14.15m3/min). The ideal lighting level in the PCBA processing plant is 800-1200LUX, with a minimum of 300LUX. When the lighting level is low, local lighting should be installed in the inspection, repair, measurement and other work areas. The optimal environmental temperature for the production workshop is 23 ± 3 ℃, generally ranging from 17 to 28 ℃, with a relative humidity of 45% to 70% RH; Set up appropriate temperature and humidity meters according to the size of the SMT surface mount processing workshop, conduct regular monitoring, and have facilities for adjusting temperature and humidity.

Service Hotline

Service Hotline